In the post has arrived the latest Greenwich Historical Society Journal - Vol.3. No.5.

It contains articles on:

The Morden College Archives - a wonderful local resource

and - and - Whaling for Oil - this is Barbara Ludlow's work on the Rise and Fall of the Enterprising Enderby's.

Can I encourage one of our readers to append a review of the journal to this posting...............

Thursday, 30 April 2009

Docklands History Group

Programme and papers from Docklands History Group. Their meetings are held at the Museum of Docklands, West India Quay at 5.30

4th June - Hugh Lyon on Forgotten Thames Shipyards of the mid-19th century

2 July - AGM and members contributions

6th August - visit to Massey Shaw

3rd September - sally Mashiter on Wapping Foreshore in Stuart Times

1st October - John Francis on the development of St. Katharine's Dock

5th November - Chris Ellmers on 1872 Dock Strike and the West India Docks

3rd December - Christmas Social.

4th June - Hugh Lyon on Forgotten Thames Shipyards of the mid-19th century

2 July - AGM and members contributions

6th August - visit to Massey Shaw

3rd September - sally Mashiter on Wapping Foreshore in Stuart Times

1st October - John Francis on the development of St. Katharine's Dock

5th November - Chris Ellmers on 1872 Dock Strike and the West India Docks

3rd December - Christmas Social.

Monday, 27 April 2009

Meridian City Hall Project-Done!

It's done!! I almost can't believe we got it finished yesterday :) If you are in Meridian, stop in at City Hall & have a look-the piece looks amazing!! Even after working on it & seeing all the pieces,I'm amazed at how good it looks in place :)

It was a long, stressful day-Kevin & I spent the morning adding the last of the copper to the star piece, as soon as we were done, around 1:30 pm, we loaded everything on the trailer & headed into Meridian. Then, we had lots of helpers to assemble all the pieces & place them on the center-pipe. Thanks so much to everyone who helped!! It was around 5 when we finally raised the completed piece into place...check out the days pics:

All the pieces layed out & ready to go....

All the pieces layed out & ready to go....

Alysa, adding the pin to hold the piece on....

Alysa, adding the pin to hold the piece on....

All the pieces layed out & ready to go....

All the pieces layed out & ready to go.... Alysa, adding the pin to hold the piece on....

Alysa, adding the pin to hold the piece on....Saturday, 25 April 2009

"Origin"-Meridian City Hall: Installation Day 1

Pics from install day one....

6:30 am

6:30 am Thanks to JAG, we had an awesome manlift for the day....it goes way up there...

Thanks to JAG, we had an awesome manlift for the day....it goes way up there... Tony & Kevin up in the air: working on the main support piece for the sculpture

Tony & Kevin up in the air: working on the main support piece for the sculpture

6:30 am

6:30 am Thanks to JAG, we had an awesome manlift for the day....it goes way up there...

Thanks to JAG, we had an awesome manlift for the day....it goes way up there... Tony & Kevin up in the air: working on the main support piece for the sculpture

Tony & Kevin up in the air: working on the main support piece for the sculptureThursday, 23 April 2009

Sneak Peekings: City Hall Project!

City Hall Project; getting closer!

My yard & house are full of huge steel pieces right now....we have set up the shade tents in the driveway the last couple days to work on the big pieces: I'm sure the neighbors don't know what to think!! Things are moving along; got almost all the wax sealer & cleanup done on everything....working on adding copper & brass today :)

We did discover a mistake yesterday & had to have some new pieces of copper cut; good thing we are ahead of schedule!!

We did discover a mistake yesterday & had to have some new pieces of copper cut; good thing we are ahead of schedule!!

Mounted the glass in the deck prism yesterday; oooooh I can't wait to do the finish treatement on it; it already looks so cool!!

Mounted the glass in the deck prism yesterday; oooooh I can't wait to do the finish treatement on it; it already looks so cool!!

We did discover a mistake yesterday & had to have some new pieces of copper cut; good thing we are ahead of schedule!!

We did discover a mistake yesterday & had to have some new pieces of copper cut; good thing we are ahead of schedule!!  Mounted the glass in the deck prism yesterday; oooooh I can't wait to do the finish treatement on it; it already looks so cool!!

Mounted the glass in the deck prism yesterday; oooooh I can't wait to do the finish treatement on it; it already looks so cool!! More updates later....got to get to work!

Wednesday, 22 April 2009

Greenwich medieval tide mill

Southwark and Lambeth Archaeological Society recently hosted a talk on the Greenwich medieval tide mill. They have been kind enough to allow us to publish their account of the talk - and also thanks for permission from Simon Davis

THE GREENWICH TIDE MILL

There was great excitement when the medieval tide mill was found at Greenwich in 2008 – with more surviving than any in Southwark. Early contact was made with Simon Davis of MoLAS, who, after a period of doubt when work was stopped due to the developer of the site being ‘credit crunched’, agreed to speak to the Southwark & Lambeth Archaeological Society on 14th April 2009. Moreover, he arranged for Damian Goodburn, generally regarded as London’s premier archaeological timber expert, to speak too.

The site of the mill is about half a mile downstream of the (erstwhile) Royal Naval College, where the Thames turns north towards the O2 (Dome). The Naval College is now Greenwich University, but was previously: the Royal Naval Hospital (Asylum) for Seamen; the Tudor Palace of Placentia; Duke Humphrey’s house; and the Lewisham house of the Abbey of St Peter of Ghent – who were there from 918 to 1414 and (probably) built the mill. The site is known as Granite Wharf.

Mr Davis began with a plan of the site, showing bore holes and evaluation trenches – none of which had revealed the mill. Then he showed a picture looking north to the 1694 Naval Powder Magazine (surrounded by a square wall), thought to be near where Enderby House is now. In the foreground the scene shows peat cutting - suggestive of good damp conditions for archaeological survival.

The mill was found during site watching, when a machine exposed some massive timber beams, some 30m from the present river front. Two were 3 ft wide, across the centre of a 6m square timber floor frame (denoted FF1 herein*), pointing towards the River. Digging revealed further floor framing (FF2) towards the river, doubling the length of the mill building. It was possible to tell that there had been two phases of flooring, and evidence for braces showed how at least the lower part of the superstructure was built. The surviving timbers had been secured to the underlying ground by piles, four of these being cradle timbers supporting the corners of FF1. There were chalk foundations, with some mill stone sherds mixed in.

There was still a plank on one side of the entry channel to the mill, leading to the head race which ran over the floor of FF1 above one of the 3 ft wide beams; FF1 would also have supported the sluice. A woven hazel panel was found - at first it was thought to be a filter, but it had a very dense weave and would have impeded the water flow. As it passed into FF2 the channel dropped down into the wheel pit, which extended across FF2 into the tail race beyond.

It is hoped that access to dig the tail race will be granted later this year. There was no sign of the mill pond, which was possibly above the levels seen in the bore holes or evaluation trenches.

Mr Goodburn described the woodwork of the mill, and how it fitted in with the changes in technology - at that time carpentry was being introduced from France (it had an Arabic origin), replacing Saxo-Norman tree wright techniques. Carpentry includes prefabricated framing, usually made flat, the joints having carpenters’ marks.

All the wood was oak, and apart from the base timber of the wheel pit, carpentry techniques were used. The large beams were felled in 1194 (dendro date), smaller timber being similarly dated. Timber conversion (cutting a trunk to size) could be just trimming square for a large beam, or splitting in half, quarters etc. Some beams were tapered, the whole trunk from the base to the first branch having been used. Boards were not sawn but cleft, giving a characteristic feathered shape; the broad end can be grooved. (Only later did mills and similar structures use elm boards.)

The base timber of the wheel pit was dug out from a single three foot wide oak log (like a dug-out canoe), curving down from the entry to the level of the tail race at the exit, which was set at -1.15m OD. Above the base timber the wheel pit had tongue & groove boarding. A part of the mill wheel was found in the pit – enough to postulate a diameter of about 5½ m, with 12 spokes and 60 paddles. The wheel was a lightweight design, having a single rim with the paddles extending either side of it. Maintenance of the wheel would have been straightforward. One paddle survived.

Mortices in the timbers for vertical posts had no residual signs of the tenons, and floor boarding had been carefully removed, indicating that the mill had been dismantled after it went out of use.

The timbers have been taken up and sent for conservation, some to York where their 4m long facility made it necessary to cut the 6m timbers. They should be impregnated with polyethylene glycol in 2-3 years.

Tidal Range. Mr Goodburn said there must have been a tidal range of 5 to 5½ m to operate the mill. Preparatory building work for the mill would have been at a spring low tide, that level being well below the tail race. Other tide mills, wharves, etc. along the Thames would also have needed such a tidal range. (Sea level has risen over the centuries, but he said that the tidal range must always have been much as it is now – current received wisdom not withstanding.)

Mr Davis, in summing up, said that the Greenwich Tide Mill was of national significance. The developer showed great interest in the mill, and was very helpful while it was being excavated. He even suggested building a replica on site, though probably not full size, as a feature to lure buyers to the proposed housing.

Apologies for any confusion caused by the FF1 and FF2 designations, which will inevitably differ from the nomenclature in any proper publication.

Richard Buchanan

THE GREENWICH TIDE MILL

There was great excitement when the medieval tide mill was found at Greenwich in 2008 – with more surviving than any in Southwark. Early contact was made with Simon Davis of MoLAS, who, after a period of doubt when work was stopped due to the developer of the site being ‘credit crunched’, agreed to speak to the Southwark & Lambeth Archaeological Society on 14th April 2009. Moreover, he arranged for Damian Goodburn, generally regarded as London’s premier archaeological timber expert, to speak too.

The site of the mill is about half a mile downstream of the (erstwhile) Royal Naval College, where the Thames turns north towards the O2 (Dome). The Naval College is now Greenwich University, but was previously: the Royal Naval Hospital (Asylum) for Seamen; the Tudor Palace of Placentia; Duke Humphrey’s house; and the Lewisham house of the Abbey of St Peter of Ghent – who were there from 918 to 1414 and (probably) built the mill. The site is known as Granite Wharf.

Mr Davis began with a plan of the site, showing bore holes and evaluation trenches – none of which had revealed the mill. Then he showed a picture looking north to the 1694 Naval Powder Magazine (surrounded by a square wall), thought to be near where Enderby House is now. In the foreground the scene shows peat cutting - suggestive of good damp conditions for archaeological survival.

The mill was found during site watching, when a machine exposed some massive timber beams, some 30m from the present river front. Two were 3 ft wide, across the centre of a 6m square timber floor frame (denoted FF1 herein*), pointing towards the River. Digging revealed further floor framing (FF2) towards the river, doubling the length of the mill building. It was possible to tell that there had been two phases of flooring, and evidence for braces showed how at least the lower part of the superstructure was built. The surviving timbers had been secured to the underlying ground by piles, four of these being cradle timbers supporting the corners of FF1. There were chalk foundations, with some mill stone sherds mixed in.

There was still a plank on one side of the entry channel to the mill, leading to the head race which ran over the floor of FF1 above one of the 3 ft wide beams; FF1 would also have supported the sluice. A woven hazel panel was found - at first it was thought to be a filter, but it had a very dense weave and would have impeded the water flow. As it passed into FF2 the channel dropped down into the wheel pit, which extended across FF2 into the tail race beyond.

It is hoped that access to dig the tail race will be granted later this year. There was no sign of the mill pond, which was possibly above the levels seen in the bore holes or evaluation trenches.

Mr Goodburn described the woodwork of the mill, and how it fitted in with the changes in technology - at that time carpentry was being introduced from France (it had an Arabic origin), replacing Saxo-Norman tree wright techniques. Carpentry includes prefabricated framing, usually made flat, the joints having carpenters’ marks.

All the wood was oak, and apart from the base timber of the wheel pit, carpentry techniques were used. The large beams were felled in 1194 (dendro date), smaller timber being similarly dated. Timber conversion (cutting a trunk to size) could be just trimming square for a large beam, or splitting in half, quarters etc. Some beams were tapered, the whole trunk from the base to the first branch having been used. Boards were not sawn but cleft, giving a characteristic feathered shape; the broad end can be grooved. (Only later did mills and similar structures use elm boards.)

The base timber of the wheel pit was dug out from a single three foot wide oak log (like a dug-out canoe), curving down from the entry to the level of the tail race at the exit, which was set at -1.15m OD. Above the base timber the wheel pit had tongue & groove boarding. A part of the mill wheel was found in the pit – enough to postulate a diameter of about 5½ m, with 12 spokes and 60 paddles. The wheel was a lightweight design, having a single rim with the paddles extending either side of it. Maintenance of the wheel would have been straightforward. One paddle survived.

Mortices in the timbers for vertical posts had no residual signs of the tenons, and floor boarding had been carefully removed, indicating that the mill had been dismantled after it went out of use.

The timbers have been taken up and sent for conservation, some to York where their 4m long facility made it necessary to cut the 6m timbers. They should be impregnated with polyethylene glycol in 2-3 years.

Tidal Range. Mr Goodburn said there must have been a tidal range of 5 to 5½ m to operate the mill. Preparatory building work for the mill would have been at a spring low tide, that level being well below the tail race. Other tide mills, wharves, etc. along the Thames would also have needed such a tidal range. (Sea level has risen over the centuries, but he said that the tidal range must always have been much as it is now – current received wisdom not withstanding.)

Mr Davis, in summing up, said that the Greenwich Tide Mill was of national significance. The developer showed great interest in the mill, and was very helpful while it was being excavated. He even suggested building a replica on site, though probably not full size, as a feature to lure buyers to the proposed housing.

Apologies for any confusion caused by the FF1 and FF2 designations, which will inevitably differ from the nomenclature in any proper publication.

Richard Buchanan

Thursday, 16 April 2009

"Origin" Updates-Final Fabrication-Day 3--done!!

Wahoo!! Finished up with the heavy fabrication today :) A few stressful moments, trying to raise the components into position, but we got it done in the end & it looks great: check out the pics from the day....

Jeronimo, the super-welder; making a few last minute welds on the star piece before we mounted it on the pipe...

Jeronimo, the super-welder; making a few last minute welds on the star piece before we mounted it on the pipe...

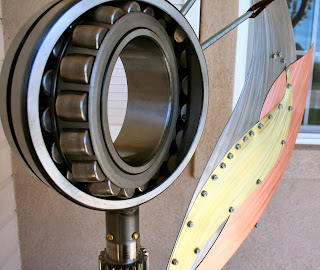

The star on the jack-stands; we had to jack it up little by little & then tip it to a 25 degree angle to join up with the support arch--this was the stress-full part of the day...

The star on the jack-stands; we had to jack it up little by little & then tip it to a 25 degree angle to join up with the support arch--this was the stress-full part of the day...

And here are all three pieces, mounted to the pole & in thier final position :)

And here are all three pieces, mounted to the pole & in thier final position :)

It was only together for about an hour; then we took everything back down, broke all the pieces into smaller parts & loaded up the trailer :)

It was only together for about an hour; then we took everything back down, broke all the pieces into smaller parts & loaded up the trailer :)

Broken down & ready to load; puzzle pieces again!!

Broken down & ready to load; puzzle pieces again!!

Now, I have a patio full of stange looking steel parts :) I'm really happy with the way everything came together; fabrication was fast & relatively easy: besides figuring out how to handle the star piece without damaging it. I think it's going to look amazing in city hall; can't wait to add the finishing touches :)

Jeronimo, the super-welder; making a few last minute welds on the star piece before we mounted it on the pipe...

Jeronimo, the super-welder; making a few last minute welds on the star piece before we mounted it on the pipe... The star on the jack-stands; we had to jack it up little by little & then tip it to a 25 degree angle to join up with the support arch--this was the stress-full part of the day...

The star on the jack-stands; we had to jack it up little by little & then tip it to a 25 degree angle to join up with the support arch--this was the stress-full part of the day... And here are all three pieces, mounted to the pole & in thier final position :)

And here are all three pieces, mounted to the pole & in thier final position :)

It was only together for about an hour; then we took everything back down, broke all the pieces into smaller parts & loaded up the trailer :)

It was only together for about an hour; then we took everything back down, broke all the pieces into smaller parts & loaded up the trailer :) Broken down & ready to load; puzzle pieces again!!

Broken down & ready to load; puzzle pieces again!!Now, I have a patio full of stange looking steel parts :) I'm really happy with the way everything came together; fabrication was fast & relatively easy: besides figuring out how to handle the star piece without damaging it. I think it's going to look amazing in city hall; can't wait to add the finishing touches :)

More updates to come...

Amber

Wednesday, 15 April 2009

"Origin" Updates-Final Fabrication-Day 2

So close to being finished today!! We probably will have a couple hours tomorrow morning to finish up; do the final test fit & then tear it down to load on the trailer :) Then, everything is coming to my place for the brass & copper, final clean up & wax sealant. :) Check out the pics of the days work:

The 2 bigger pieces; layed out & ready to be mounted on the center-pole. We started with the circular piece in the background....

The 2 bigger pieces; layed out & ready to be mounted on the center-pole. We started with the circular piece in the background....  Jeronimo (with a J) the super-welder; preparing to mount the piece onto the centerpipe...

Jeronimo (with a J) the super-welder; preparing to mount the piece onto the centerpipe...  Heating up the big scale to bend it to the right angle to capture the round piece: all the pieces sit at an angle, so we had to match up the supports.

Heating up the big scale to bend it to the right angle to capture the round piece: all the pieces sit at an angle, so we had to match up the supports.  Here is the first scale-supporting the roundish piece. Jeronimo welding the triangle piece into place.

Here is the first scale-supporting the roundish piece. Jeronimo welding the triangle piece into place.

First two pieces; in place & ready to go!

First two pieces; in place & ready to go!  The star piece; this one is the most complicated, by far--to support & get mounted correctly.

The star piece; this one is the most complicated, by far--to support & get mounted correctly.

My fav. pic of the day :P

My fav. pic of the day :P

The 2 bigger pieces; layed out & ready to be mounted on the center-pole. We started with the circular piece in the background....

The 2 bigger pieces; layed out & ready to be mounted on the center-pole. We started with the circular piece in the background.... Jeronimo (with a J) the super-welder; preparing to mount the piece onto the centerpipe...

Jeronimo (with a J) the super-welder; preparing to mount the piece onto the centerpipe... Heating up the big scale to bend it to the right angle to capture the round piece: all the pieces sit at an angle, so we had to match up the supports.

Heating up the big scale to bend it to the right angle to capture the round piece: all the pieces sit at an angle, so we had to match up the supports. Here is the first scale-supporting the roundish piece. Jeronimo welding the triangle piece into place.

Here is the first scale-supporting the roundish piece. Jeronimo welding the triangle piece into place. First two pieces; in place & ready to go!

First two pieces; in place & ready to go! The star piece; this one is the most complicated, by far--to support & get mounted correctly.

The star piece; this one is the most complicated, by far--to support & get mounted correctly.  My fav. pic of the day :P

My fav. pic of the day :PTomorrow, we will finish up the star; mount it to the pole & do the final test fit. Then, the whole thing will be broken down into manage-able pieces; we designed it to come apart---the pieces all bolt together: they have to fit through the front door of City Hall....

I can't wait to see the copper on it!! That will happen later this week & this weekend.

More pics to come: stay tuned!!

Amber

Tuesday, 14 April 2009

More Merryweather

- a long and interesting letter about Merryweathers from the Glenister family of Grove Park:

Mr. Glenister writes to say he is the great grandson of William Montague Glenister who was involved with the Merryweather fire tricycle. He has a copy of the original patent and would happy to share this with anyone who is interested. He also had pictures of Merryweather engines - one of which was sold to St.Albans Fire Brigade and was used in the Coronation Procession of George V in 1911. He also has a photo of an engine on display at Floors Castle in Kelso.

He says William Glenister met Mr. Merryweather in Hastings where he thinks Merryweathers had a factory and they designed engines together there. William founded the first Volunteer Fire Brigade in the country in Hastings in 1861, which is how they met. He was the Captain of this first Fire Brigade and also Chief Constable of Police. The modern family has the first hand carved ivory fireman's whistle, on a gold chain, presented to William Glenister for this.

We need to know more!!!

Mr. Glenister writes to say he is the great grandson of William Montague Glenister who was involved with the Merryweather fire tricycle. He has a copy of the original patent and would happy to share this with anyone who is interested. He also had pictures of Merryweather engines - one of which was sold to St.Albans Fire Brigade and was used in the Coronation Procession of George V in 1911. He also has a photo of an engine on display at Floors Castle in Kelso.

He says William Glenister met Mr. Merryweather in Hastings where he thinks Merryweathers had a factory and they designed engines together there. William founded the first Volunteer Fire Brigade in the country in Hastings in 1861, which is how they met. He was the Captain of this first Fire Brigade and also Chief Constable of Police. The modern family has the first hand carved ivory fireman's whistle, on a gold chain, presented to William Glenister for this.

We need to know more!!!

Crossness progress

Good news in the Crossness newsletter. Much detail about the ongoing work and how they are spending all the money they have been given.

Wish they would agree to come to GIHS and talk to us about it - why do they always say 'yes' and then never book a date???

- and also a long article about tracking down the ownership record of a traction engine and much else fascinating stuff!

Wish they would agree to come to GIHS and talk to us about it - why do they always say 'yes' and then never book a date???

- and also a long article about tracking down the ownership record of a traction engine and much else fascinating stuff!

Notes and queries

Some recent queries - can anyone help?

Email from the Brookwood Cemetery Society who are researching a group of memorials to the Goodwin family. They want information on a Henry Goodwin who was a retired iron founder living in Blackheath Hill in the 1880s.

I have been very kindly sent a HUGE package of stuff about Grieg's wharf which was on the Peninsula. The author would be interested in additional information. He also has information about ship-builder Courtney who was also on the Peninsula (and who I had failed to find anything out about myself when I wrote 'Greenwich Marsh'.

Note from a lady who is the great granddaughter of Francis who founded the tin box makers of Blackheath Hill. She has memories of visiting the factory as a child.

Note from someone who wants information about George Hardstaff who was harbour master at Woolwich in the late 19th century. Also George McLuckie who had a cycle manufacturing business in Erith High Street and later became involved in marine engineering in Woolwich, and his son also George McLuckie who worked in armament manufacture at Woolwich in the Second World War.

More Merryweather - a correspondent wants info on small Merryweather engines.

Query from an american numisologist - he has evidence from 1780s of copper coins minted in Greenwich. Do we know anything about this? has anyone any info??

Email from someone who has a painting for sale of Greenwich Power Station.

We can forward any responses to these on.

Email from the Brookwood Cemetery Society who are researching a group of memorials to the Goodwin family. They want information on a Henry Goodwin who was a retired iron founder living in Blackheath Hill in the 1880s.

I have been very kindly sent a HUGE package of stuff about Grieg's wharf which was on the Peninsula. The author would be interested in additional information. He also has information about ship-builder Courtney who was also on the Peninsula (and who I had failed to find anything out about myself when I wrote 'Greenwich Marsh'.

Note from a lady who is the great granddaughter of Francis who founded the tin box makers of Blackheath Hill. She has memories of visiting the factory as a child.

Note from someone who wants information about George Hardstaff who was harbour master at Woolwich in the late 19th century. Also George McLuckie who had a cycle manufacturing business in Erith High Street and later became involved in marine engineering in Woolwich, and his son also George McLuckie who worked in armament manufacture at Woolwich in the Second World War.

More Merryweather - a correspondent wants info on small Merryweather engines.

Query from an american numisologist - he has evidence from 1780s of copper coins minted in Greenwich. Do we know anything about this? has anyone any info??

Email from someone who has a painting for sale of Greenwich Power Station.

We can forward any responses to these on.

"Origin" Updates-Final Fabrication

We spent the day at Boise Iron Works today: final fab for the Meridian City Hall sculpture :) They graciously let us take over the back part of the shop to put together the pieces & do a test assembly---our ceilings are not high enough.... Check out the pics:

Laying out all the puzzle pieces....

Laying out all the puzzle pieces.... Geronimo; laying down perfect welds :)

Geronimo; laying down perfect welds :) Making progress on the compass rose piece.....

Making progress on the compass rose piece.....

A look at all 3 pieces: tomorrow we will put them on the pole for a final test fit: then take everything apart, take the pieces home, attach copper/brass, wax everything; then off to city Hall next week for installation!! A busy couple of weeks coming up; I'm excited to be making progress on the project :)

Laying out all the puzzle pieces....

Laying out all the puzzle pieces.... Geronimo; laying down perfect welds :)

Geronimo; laying down perfect welds :) Making progress on the compass rose piece.....

Making progress on the compass rose piece.....

A look at all 3 pieces: tomorrow we will put them on the pole for a final test fit: then take everything apart, take the pieces home, attach copper/brass, wax everything; then off to city Hall next week for installation!! A busy couple of weeks coming up; I'm excited to be making progress on the project :)

More updates to come; for now, I need to take a bath :)

Sunday, 12 April 2009

Leafy Sail Sculpture Done :)

Sunday, 5 April 2009

Updates: garden make-over, new sculpture, etc..

This cute little sculpture has been sitting in the shop for weeks now, just waiting for some TLC :) I finally got to work on it yesterday & am almost done: in the pic, it's just in mock-up stage: afterwards I took the brass, copper, & stainless off & textured them with the grinder; gives a beautiful, dimensional finish, but takes forever! Then, put them all back together again to rivet together & discovered that some of the holes I drilled were too big for a clean rivet tail: I must say, my skills at drilling through 4 layers of thin stuff & having everything line up in the end are lacking....but oh well. New plan; will get some cute little nuts & bolts today to attach everything--I like little bolts anyway--maybe I'll even get some colored washers too... Anyway, then I'll be able to mount the sail thing to the piece & it will be done!! It's a spinner, btw....also notice that my sail has a remarkable resemblance to leaves---I must have gardening on the brain!!

This cute little sculpture has been sitting in the shop for weeks now, just waiting for some TLC :) I finally got to work on it yesterday & am almost done: in the pic, it's just in mock-up stage: afterwards I took the brass, copper, & stainless off & textured them with the grinder; gives a beautiful, dimensional finish, but takes forever! Then, put them all back together again to rivet together & discovered that some of the holes I drilled were too big for a clean rivet tail: I must say, my skills at drilling through 4 layers of thin stuff & having everything line up in the end are lacking....but oh well. New plan; will get some cute little nuts & bolts today to attach everything--I like little bolts anyway--maybe I'll even get some colored washers too... Anyway, then I'll be able to mount the sail thing to the piece & it will be done!! It's a spinner, btw....also notice that my sail has a remarkable resemblance to leaves---I must have gardening on the brain!! And speaking of gardening; we installed the path last night--made from lovely recycled concrete squares that cost us nothing :) This path is for getting the lawn mower from the shed to the front of the house easily; since I still have some lawn to mow...

And speaking of gardening; we installed the path last night--made from lovely recycled concrete squares that cost us nothing :) This path is for getting the lawn mower from the shed to the front of the house easily; since I still have some lawn to mow...

And here it is all done; I even transplanted some thyme from the other side garden, to grow between the squares :) Hopefully it will fill in nicely & smell yummy when anyone walks down the path. Next, it's on to planning out my plantings: still a couple weeks to go before I can start planting warm weather seeds anyway...

On the City Hall front: we are scheduled for fabrication & final assembly this week!!! OMG--I'll be welding up the brackets today, meeting with Lex tomorrow morning to plan the build, & then putting it all together on Tues/Wed. Hopefully it will all go relatively smooth--can't wait to see things come together!!! Will take lots of pics & update often....

Amber

Subscribe to:

Comments (Atom)

Assembly complete; almost ready to raise it into place :)

Assembly complete; almost ready to raise it into place :) Adding the plumb-bob: the finishing touch!

Adding the plumb-bob: the finishing touch!

Geronimo; the super-welder!

Geronimo; the super-welder!